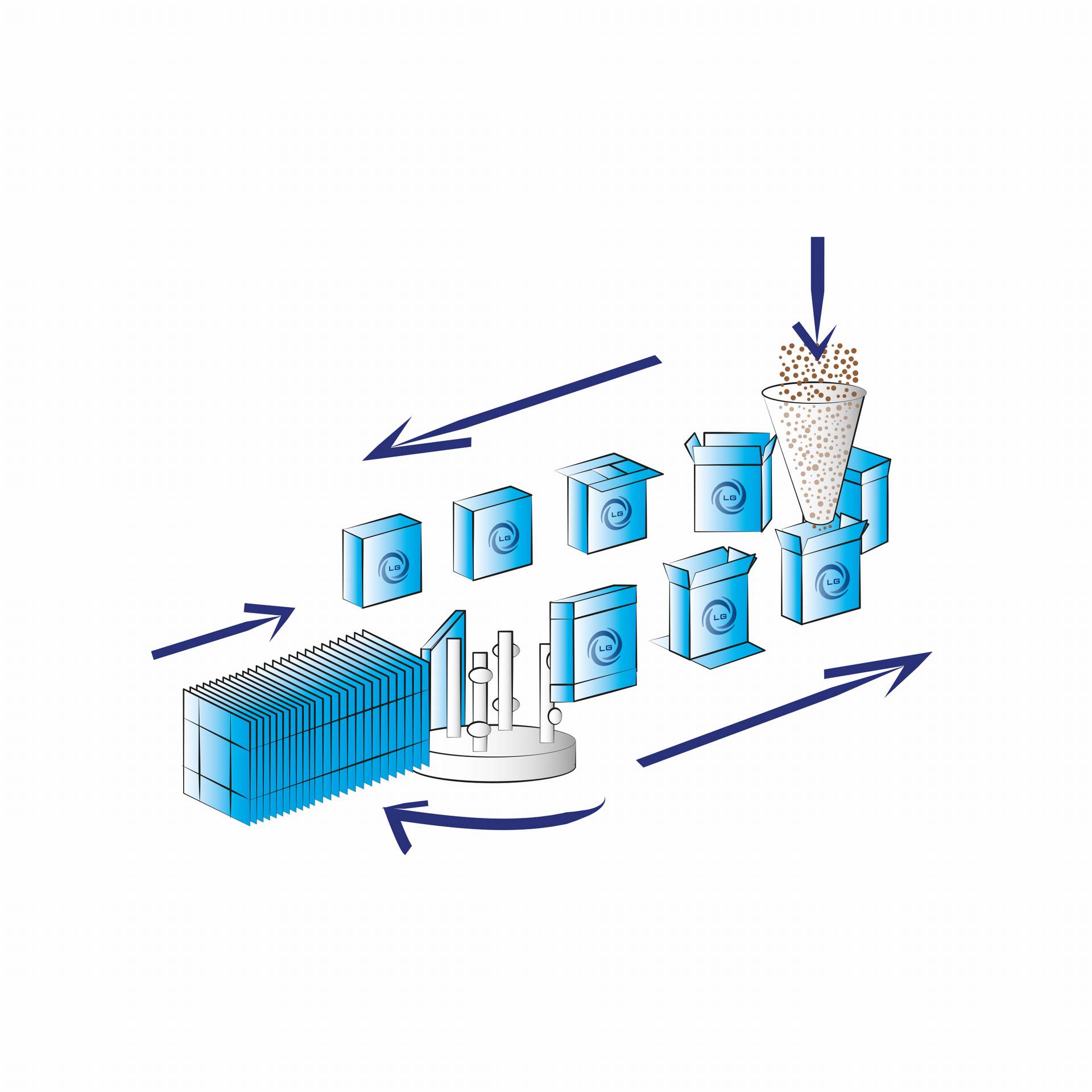

LG Automation vertical cartoners are mechanically robust, easy-to-use both in semi-automatic and fully automatic configuration.

Vertical cartoners are typically used to pack in pre-glued cartons a large variety of products such as cereals, chocolates, pasta, cous cous, snacks, rice, salt, sugar, cookies, biscuits, bakery products, sweets, candies, dry fruit, frozen food, cheese, spices, sodium bicarbonate, herbicide, powder detergents, FMCG, chemical products, pet food

LG Automation vertical cartoners are the ideal tool to pack a wide range of products, both loose or pre-packaged from 20 bpm in semi-automatic version and up to 350 cartons/minute in fully automatic configuration.

Changeover typically below 10 minutes, with optional possibility to servo-drive thus automatically perform most changeover adjustments and regulations

LG Automation has the right experience to supply not only the “simple” stand alone machinery but also the turnkey machinery with one or multiple dosing systems adequate for your product: volumetric cup dosing heads, multi-head weigher, linear weigher and counting systems.

As a standard feature, all LG Automation machineries integrate positive carton opening and various types of closing systems: flap-in, traditional tuck-in, reverse flap labyrinth sequence, crash-lock and gable top.

Thanks to a fully automatic design with integration of servo-drives and special mechanical solutions, LG Automation vertical cartoners pack at high speed and ensure operator friendly design, extreme hygiene, quick format changeover and extreme efficiency.

In addition to traditional cartons, LG Automation cartoners can pack cartons with special shapes such as for instance truncated pyramid shapes, hexagonal shapes, concave or convex sides.

Optional features may include gadget/scoop insertion, spout application

LG Automation cartoners impress thanks to very small footprint, high productivity, quick and intuitive format changeover