LG Automation machines are ideal to rinse, in-line filling, capping and closing a large variety of plastic and glass containers such as bottles, flacon, jars, aerosol…

Our machines are ideal for a large variety of products such as chemical, home care, gel, personal care, FMCG, creams, herbs, food sauces, oil, liqueurs, products of house cleaning, disinfectants for hands, liquid soap, cosmetics, ketchup, tomato sauce, mayonnaise, honey, detergents, HPC, chemical, super-alcoholic drinks

LG Automation machines are designed to efficiently deal with all types of closures including pressure, aluminum screw caps, pre-threaded, oriented, dispenser and trigger at low, medium and high production also with pumps or triggers insertion.

Thanks to a mechanically robust structure and continuous optimizations these machines comply with highest FDA standards in terms of hygiene, cleaning, easy-of-use and resistance.

In single head capping configuration, this cost-effective machine is ideal both for small productions and also to successfully assemble the most complex types of closures that require the highest flexibility. To ensure top flexibility each capping head is driven by an independent servomotor so to align asymmetric caps by applying the necessary torque to rotate the caps as needed

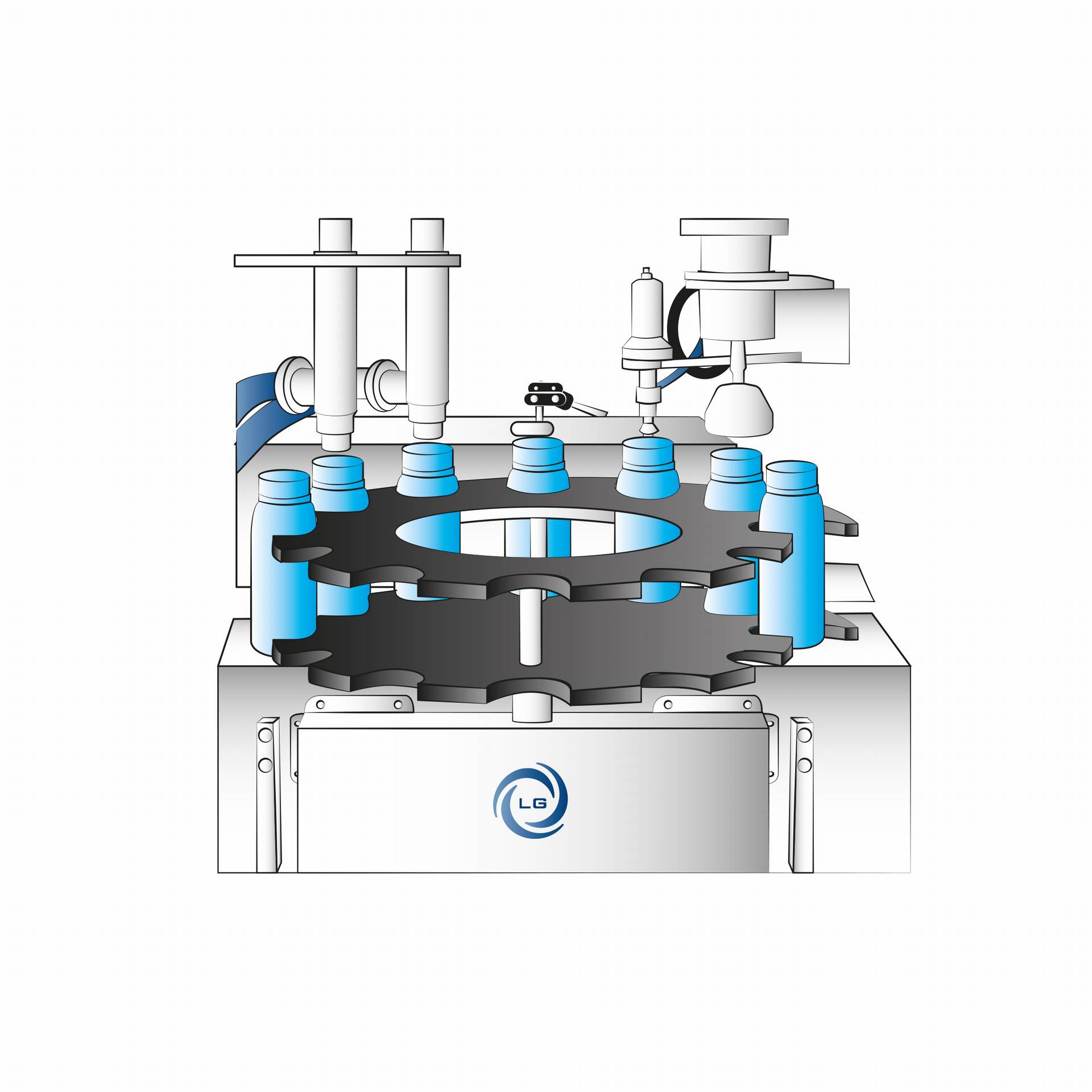

In addition, we can also supply multi-head rotary cappers that are particularly suitable for medium and high production volumes up to 500bpm

All above mentioned machines integrate an intuitive HMI control panel to benefit of the highest flexibility and control several process variables that include setting of all rotation parameters of each head, torsional strength and quick automatic set up on the specific container height

Thanks to the experience acquired on the field, in addition to the “simple” stand alone machinery our turnkey supply can also include product dosing, filling, capping, conveying, labelling, case packing and palletizing